Automating CAD Tasks in SolidWorks

Computer-Aided Design (CAD) software like SolidWorks is one of the most widely used tools in mechanical and manufacturing design, helping engineers create precise 3D models and detailed documentation. But behind the creativity lies a problem: too much time is spent on repetitive, manual work—suppressing components, updating drawings, arranging BOM balloons, and other routine tasks. While essential, these steps add little creative value, slow projects, and increase the risk of errors.

To overcome this challenge, we developed a suite of custom SolidWorks add-ons. By removing repetitive work and enforcing consistency, these tools free engineers to focus on what matters more: creating innovative, accurate, and optimized designs.

Problem Statement

Engineers and designers often spend significant time performing tasks that are repetitive in nature, such as:

- Suppressing or un-suppressing multiple components.

- Controlling component visibility (hide/unhide).

- Creating holes.

- Identifying specific components and applying required operations.

- Replacing components with other required parts.

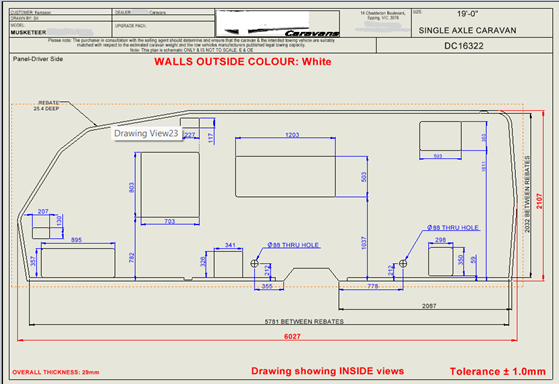

- Updating drawing documents to reflect real-time changes.

- Creating and arranging Bill of Materials (BOM) balloons.

- Checking and correcting rebuild errors or missing references.

These manual steps reduce productivity, cause delays, and increase the risk of inconsistencies and human error.

Our Solution

We designed and implemented a suite of SolidWorks automation add-ons that streamline these repetitive processes. Key features include:

- Component Control Automation

- Automatically suppresses/un-suppresses components.

- Manages visibility toggling (show/hide) based on defined rules.

- Hole Creation

- Integrates with SolidWorks Hole Wizard to auto-generate required holes on components.

- Component Operations

- Identifies specific parts by defined criteria.

- Executes operations such as modification, validation, or replacement.

- Component Replacement

- Automates swapping of parts with required alternatives while maintaining assembly integrity.

- Material Assignment

- Automates the assignment of predefined colors and standard materials (e.g., PVC Board, Fascia Board, and ABS Melamine) to door components.

- Interference Detection

- Identifies and flags potential overlaps before release.

- Export Automation

- Automates batch export of models and drawings to multiple formats (e.g., PDF, DXF, Parasolid).

- Ensures consistent naming conventions and organized folder structures during export.

- Drawing Document Synchronization

- Ensures updated 3D models are accurately reflected in 2D drawings.

- Reduces discrepancies between design and documentation.

- BOM Balloon Automation

- Automatically generates and positions BOM balloons in drawing documents.

- Ensures all parts are accounted for and visually clear.

Impact

The automation add-ons delivered measurable improvements:

- 50% reduction in time spent on repetitive tasks.

- Improved drawing and BOM accuracy through standardized, rule-based automation.

- Minimalized errors through standardized, rule-based automation.

- Boosted overall productivity, enabling engineers to dedicate more time to innovation, validation, and optimization instead of manual rework.

Conclusion

By building customized SolidWorks add-ons, we successfully streamlined CAD workflows and improved design efficiency. This project highlights the value of CAD automation in reducing manual effort, minimizing errors, and enabling engineers to deliver high-quality designs faster.