Bangladesh has long been recognized as a global manufacturing hub, particularly in the Ready-Made Garments (RMG) sector. The rhythmic sound of sewing machines and the bustling energy of our factories have driven economic growth. But now, the tides of change are rising. The demands of the Fourth Industrial Revolution (Industry 4.0) are knocking at our door, and in order to stay competitive, Bangladesh must evolve from being a labor-intensive hub to one of innovation and automation.

At the heart of this industrial transformation are two powerful technologies: CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing). Together, these technologies will redefine the future of manufacturing in Bangladesh. And the architects of this new era? Our brilliant software engineers.

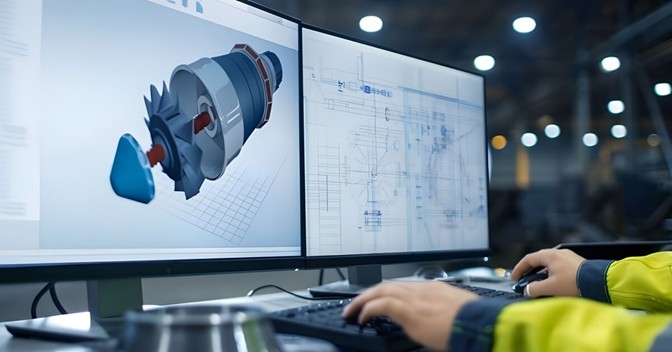

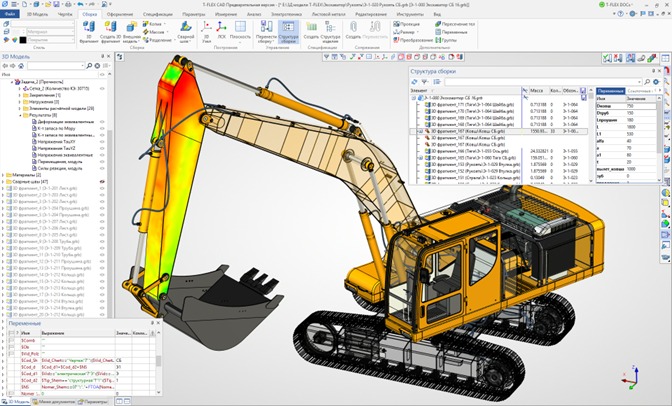

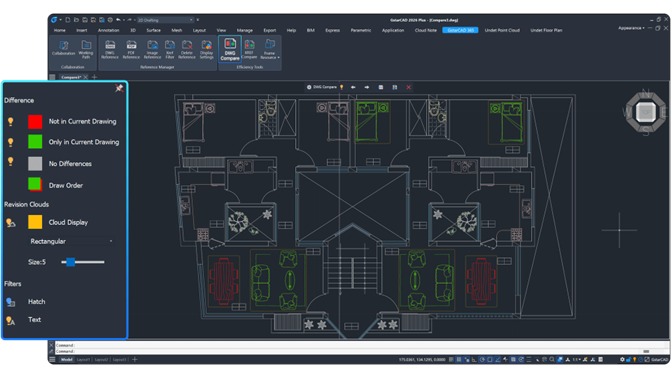

In the world of software engineering, CAD is comparable to the UI/UX design phase for physical products. It’s where engineers and designers create precise 2D and 3D models for anything from simple bolts to complex automotive parts and even entire buildings.

CAM, on the other hand, is the engine behind turning these designs into reality. Once the digital model is ready in CAD, CAM software generates the machine code (like G-code) that instructs manufacturing machinery, CNC machines, 3D printers, and robotic arms on how to produce the part or product.

Together, CAD and CAM form the backbone of modern, automated manufacturing, and they are paving the way for Industry 4.0.

The adoption of integrated CAD/CAM systems is not just an upgrade but a strategic necessity for Bangladeshi industries to stay competitive in the rapidly evolving global market. Here’s how these technologies can shape the future of manufacturing in Bangladesh:

Diversification Beyond RMG:

While the Ready-Made Garment sector remains strong, Bangladesh has enormous potential in light engineering, electronics, automotive parts, furniture, and medical devices. These sectors demand high precision and complexity, which is only achievable with CAD/CAM technologies. Adopting these systems will allow Bangladeshi manufacturers to produce intricate, high-value goods, reduce reliance on imports, and open new avenues for exports.

The Rise of the “Smart Factory”:

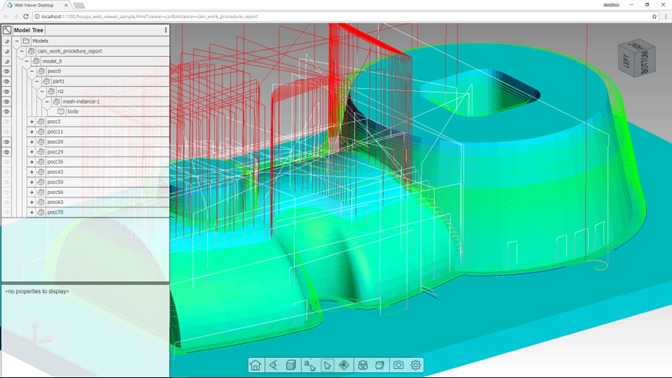

Incorporating CAD/CAM systems into Industry 4.0 creates the possibility for the rise of “smart factories.” When coupled with IoT sensors and data analytics, factories can achieve unprecedented efficiency. The creation of Digital Twins (virtual replicas of products or production lines) enables manufacturers to simulate the entire process before production begins. This reduces downtime, optimizes toolpaths, and enhances maintenance predictions, leading to a reduction in waste and improved operational efficiency.

Mass Customization:

Mass production is no longer enough. The future of manufacturing lies in mass customization. Imagine a furniture company allowing customers to design their own products online. With CAD, customers can submit their designs directly to the factory, where CAM systems direct machines to create the product with precision. This level of customization will differentiate companies in competitive markets and cater to growing consumer demand for personalized products.

Rapid Prototyping and Innovation:

Thanks to 3D printing (a form of additive manufacturing powered by CAM), companies can go from a CAD model to a physical prototype in hours, not weeks. This drastically shortens the R&D cycle, fosters a culture of innovation, and allows Bangladeshi companies to adapt to market trends and demands faster than ever before.

At the intersection of software and manufacturing is the critical role of software engineers. Without their expertise, the full potential of CAD/CAM cannot be unlocked. Here are a few ways software engineers drive innovation in manufacturing:

Automation Scripting and Plugin Development:

While standard CAD/CAM software is powerful, it often needs customization to suit the unique workflows of each factory. Software engineers can write scripts and plugins (using languages like Python, C++, or C#) to automate repetitive tasks, generate toolpaths, and create custom design validation checks. This leads to significant time savings and reduces human error.

Integration Specialists:

To create a truly smart factory, software engineers are required to integrate CAD/CAM systems with other enterprise software systems, such as ERP (Enterprise Resource Planning), MES (Manufacturing Execution Systems), and PLM (Product Lifecycle Management). This integration ensures smooth data flow between design, production, inventory, and finance systems, leading to better decision-making and streamlined operations.

Data and AI/ML Engineers:

The data generated by the CAM process, such as machine performance, tool wear, and production times, is invaluable. AI/ML engineers can harness this data to create predictive maintenance models, detect defects in real time, and optimize production processes. These technologies are pivotal in reducing downtime, improving quality control, and boosting factory efficiency.

Simulation and Visualization Experts:

The development of Digital Twins requires expertise in 3D graphics, physics simulation, and data visualization. Software engineers skilled in these areas help create virtual environments where factories can simulate production, perform training, and identify design flaws before implementation. Additionally, technologies like AR (Augmented Reality) and VR (Virtual Reality) can be used to improve training, guide assembly, and even assist with remote monitoring and diagnostics.

For Manufacturing Companies:

Bangladeshi manufacturers need to invest not just in machinery but in the software talent that can maximize their ROI. It’s time to think beyond mechanical engineers and build in-house or partnered software teams focused on automation, robotics, and CAD/CAM integration.

For the Software Industry:

The manufacturing sector represents a vast, untapped market for custom software solutions, integration services, and high-tech consulting. The future is in industrial automation software development, and this is a unique opportunity for Bangladesh’s software industry to diversify beyond fintech and e-commerce.

For Academia:

It’s essential for universities to strengthen collaboration between computer science and mechanical engineering departments. Curricula should include courses in industrial automation, robotics, and CAD/CAM API programming to produce a skilled workforce ready to drive this transformation.

The next chapter in Bangladesh’s growth will not be written solely on fabric. It will be coded in Python, designed in SOLIDWORKS, and executed by automated machinery. The future of manufacturing in Bangladesh lies in the seamless integration of design and technology, precision, and innovation. By harnessing the power of CAD/CAM, we can transition from being a labor-intensive hub to a beacon of high-tech, world-class manufacturing.

With a strategic focus on software, automation, and digital integration, Bangladesh can position itself as a global leader in the manufacturing revolution, making “Made in Bangladesh” synonymous with excellence, precision, and technological sophistication.